COLLABORATION. DESIGN. TESTING. QUALITY SYSTEMS

Our products start with our designer’s passion and creativity with good engineering leadership. InSource Design & Manufacturing Technologies product manufacturing provides a solid pathway to a successful product launch. Our design process for Manufacturing is treated as a mandatory framework for every new project that comes through our facility while following our mandatory step by step ISO 9001:2015. Our integrated process infrastructure was created to handle every project, to help us effectively communicate a thorough review of documentation by our engineering team.

DESIGN PROCESS

At InSource Design & Manufacturing Technologies our design process can be used to achieve several different outcomes and the most important QUALITY, ACCURACY and REPEATABILITY in military and Defense applications from purchasing through production and shipping.We adopt original Design, Adaptive Design, Redesign and Selective Design and we follow a 3 phase design process.

Phase 1 : Conceptual design

- Define problem (problem statements, product dissection and refine of PDS)

- Gather information (Special Requirements and project scope )

- Concept Generation

- Evaluation of concept

Phase 2: Embodiment Design

- Product architecture for arrangement of physical element modularity

- Configurarion design for preliminary selection of material and manufacturing modeling processes

- Parametric Design by setting Robust Design, set tolerances DFM, DFA, DFE

Phase 3: Detail Design

- The Design is brought to the stage of a complete engineering and manufacturing description of a tested and producible product.

- Detail engineering drawing

- Verification testing of prototype

- Assembly drawing and instruction is completed

- Detail cost estimate and concluded with a final design review with the client before the decision is made to go on the manufacturing floor.

With these 3 phases, InSource Design & Manufacturing Technologies will take your design to the real world. We also add various consideration of good design in achievement of performance requirement, life cycle issues, environmental and regulatory issues.

COLLABORATION

We invite you to provide us with your complete documentation you have, including legacy, Gerbers, CAD files, assembly drawings, fab drawings, schematics, test procedures, BOMs, other special instructions and even prototypes, if you already have them. We will work with you to discuss expectations, timelines and critical parameters and identify any bottleneck that stand between you and your desired goal. We can create and implement a plan to quickly address any issues so we can move on building your product that meet or exceed your expectation.

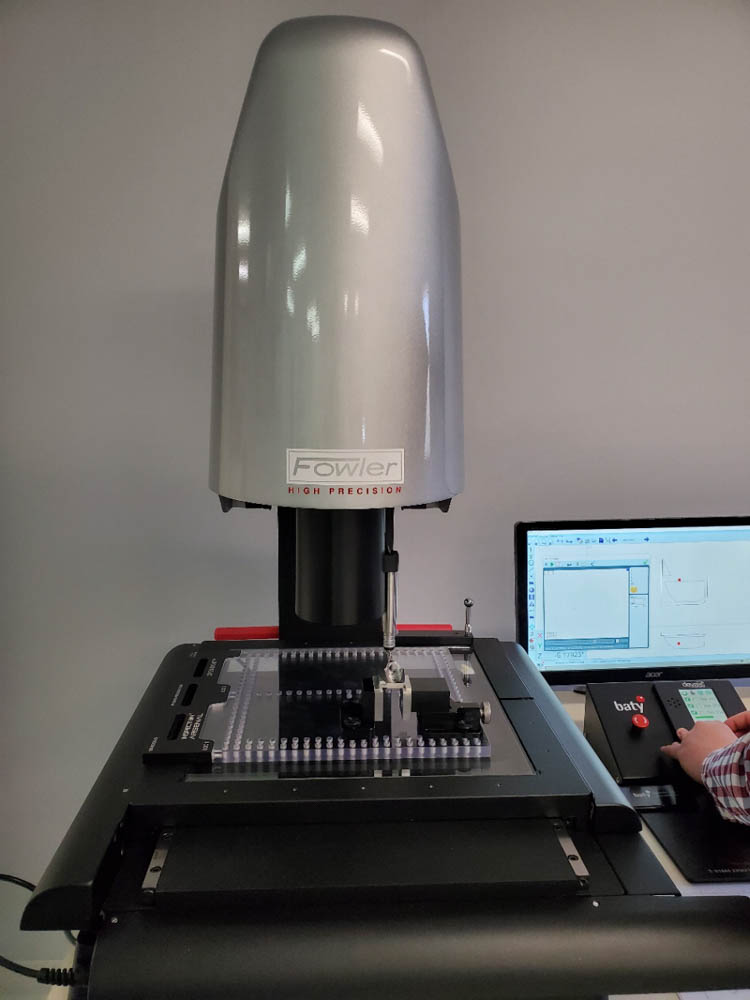

TEST SOLUTION

- Review of documentation to determine test strategy

- Fixture design

- Material procurement of all fixture-related components

- Test fixture assembly

- Program validation

- Test validation – debug and fault verification

- Full set of test equipment documentation (BOM, schematic, scope of work, and validation data)

SYSTEMS INTEGRATION

- Custom box assemblies, consoles, cabinets, enclosures and rack-mount systems

- Electronic and Electro-Mechanical Assemblies

- Large Scale Integration of Electrical and Mechanical Sub-Assemblies into Final Systems or Products

- Complete system builds and full integration of multiple subassemblies

- Pneumatic, hydraulic and servo-activated products

- High-reliability soldering and assembly

- Full burn-in of complete systems

- Full Testing and verifications of product