Additive Manufacturing & 3D Printing

CAD to Production Parts in Days

When you are ready to take your parts from CAD to finished production quality 3D printed parts, InSource has the knowledge, technology, and commitment to quality that you want.

InSource DMT runs state-of-the-art 3D printers from Markforged, Formlabs, and Ultimaker 5S. With a large selection of materials featuring different characteristics we can 3D print your parts exactly to your specifications

Throughout the entire process your project is handled by an experienced technician and engineer that will ensure your parts are perfect. We can also advise on the best material choice for your project and assist with CAD design if needed.

Rigid quality assurance and control mean consistency with your parts. All parts are inspected after printing.

Selective Laser Sintering (SLS) 3D Printing

Our SLS additive manufacturing is the perfect solution for manufacturing high quality production ready parts in Nylon 11 & Nylon 12 materials. A cost effective 3D printing solution for rapid prototyping and end-user quality parts. Idea for low to medium volume.

Nylon 11 Features

- 49 MPa Tensile Strength

- 40% Elongation at Break

- Impact resistant

- Thin walled ducts and enclosures

- Ideal for snaps, clips, hinges

- Orthodics and Prosthetics

Nylon 12 Features

- 50 MPa Tensile Strength

- 11% Elongation at Break

- Ideal for High performance prototyping

- Small batch manufacturing

- Jigs, fixtures, & tooling

- Biocompatible, sterilizable part

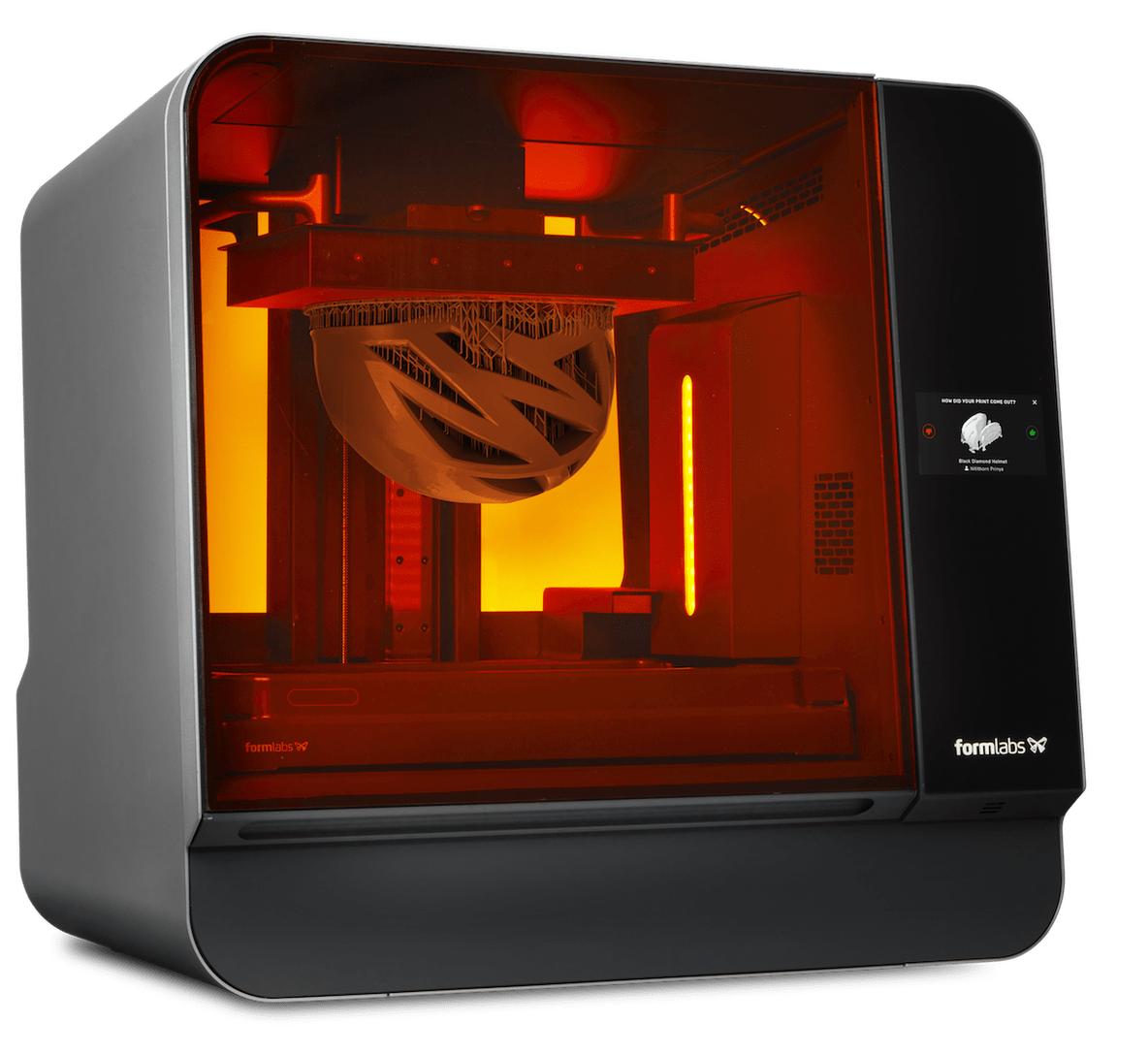

Stereolithography (SLA) 3D Printing

Meeting complex demands in today’s competitive market. Insource Design and Manufacturing Technologies is Embracing stereolithography (SLA) 3D printing with a system built completely on new Print process Launch from form lab on their new M3 and M3L 3D printers. With our fleet of SLA printers and wide range of advanced engineering materials, we can support highly diverse research projects. Insource will Translate your digital Design into very High accuracy quality functional parts with fine features and smooth finish surfaces.

Either for industrial design, Engineering and product Design, Automotive, Medical, Aerospace and Defense, food industry we have the capability to print advanced materials to meets your concept or custom design.

Our list of of advanced photopolymer resin materials:

1.Engineering resins

- Tough

- Rigid

- Durable and flexible

- Elastic

- High Temp

- Gray pro

- Durable

Our standard resins provide high resolution as well and are well suited for the medical industry.

XY resolution is from 25 micron to 300 micron

Fuse Deposition Modeling (FDM)

FDM Printers build the parts layer by layer from strong thermoplastics and can run faster and generally at a lower cost than the SLA printers, however the finish quality is not as smooth. When cost and time are more important than the smoothness of the finished product the FDM printer can be a good choice.

High-Strength Reinforced 3D Printing

3D Printed Carbon Fiber!

When you need the strongest parts we can print high-strength carbon fiber reinforced parts. The unique 3D printing process reinforces the printed part with fiber material, such as carbon fiber or kevlar,.

Request a Quote

Our Additive Manufacturing Facility Equipment

SLA 3D Printing

Technical Specifications

Build Volume

13.2 × 7.9 × 11.8 in

Layer Height

25-300 Microns

Materials

Over 20 resin options to produce parts for just about any application

Standard Resins: Outstanding performance. Excellent detail.

Engineering Resins: Functional prototyping materials.

Jewelry Resins: High-detail materials for jewelry design and clean investment casting.

Dental Resins: Professional Materials for digital dentistry.

Ceramic Resins: Ceramic Resin can be fired to create a fully ceramic piece.

Selective Laser Sintering (SLS)

Technical Specifications

Build Volume

6.5 6.5 × 11.8 in

Maximum Part Size

6.3 x 6.3 x 11.6 in

Layer Thickness

110μm

0.004in

Materials

Nylon 11 & Nylon 12

Fuse Deposition Modeling (FDM)

Technical Specifications

Build Volume

12.99 x 9.44 x 11.8 in

High-Strength Materials

Over 230 different materials based on application, PLA, PTG