Request a Quote

Design to Manufacture

RAPID PROTOYPING, PRODUCT ENGINEERING & CONTRACT MANUFACTURING

FROM CONCEPT TO PROTOTYPE TO PRODUCTION

We are a full service rapid prototyping and contract manufacturing facility in Merrimack, NH, offering expertise in the field of:

- Mechanical Engineering

- Product Design & Engineering

- Electronic Components & Devices

- Rapid Prototyping & Production-ready

- Material Selection

- Precision Product Engineering & Development

- Development & and custom components Manufacturing

- Build-to-Print Manufacturing

Onsite Technical Capabilities

- CNC Machining, Milling & Turning

- Additive Manufacturing/3D Printing

- Laser Marking

- Precision Measuring & Quality Inspection

- Industrial Oven for Heating, Drying, & Testing

- CAD

TRUST your products in the hands of a team who share the same passion and desire for perfection. Whether it is in the early stages of concept & design, late stage prototyping, or in production, we use our expertise and experience to achieve the highest quality, reliability and functionality for your parts and products.

Our COMMITMENT to you is to dedicate our resources and seek those needed to ensure your project succeeds.

TRUST. INTEGRITY. COMMITMENT.

Call (603) 997-7704 to discuss your project.

What We Do

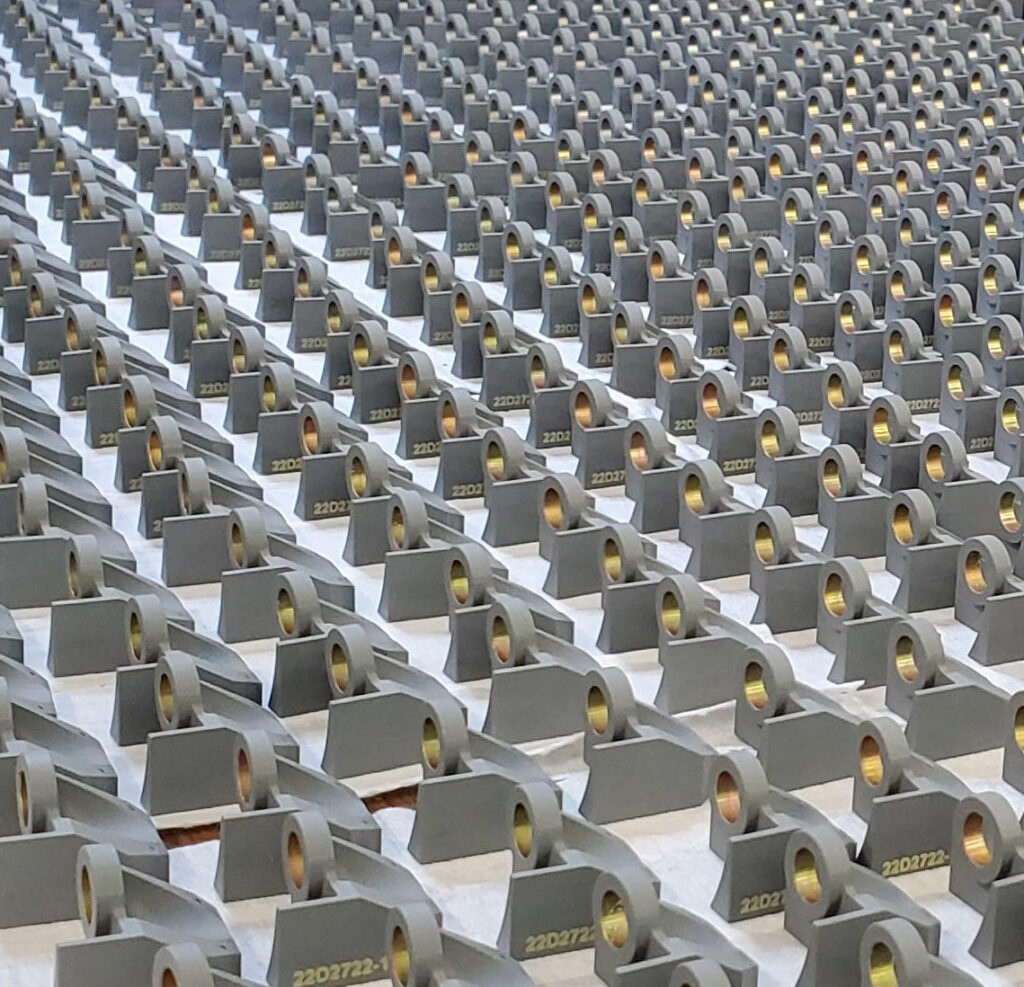

Our CNC Machining facility can produce high precision parts for fast prototyping and manufacturing.

- CNC 5-Axis Milling

- CNC Turning

- Low to Medium volume production

- Various metal types. Aluminum to High Grade Aerospace metals

- Plastic such as Delrin.

- Master Cam 2021

- Machining parts for Commercial, Medical, Automotive, Military and Defense, Automation and more

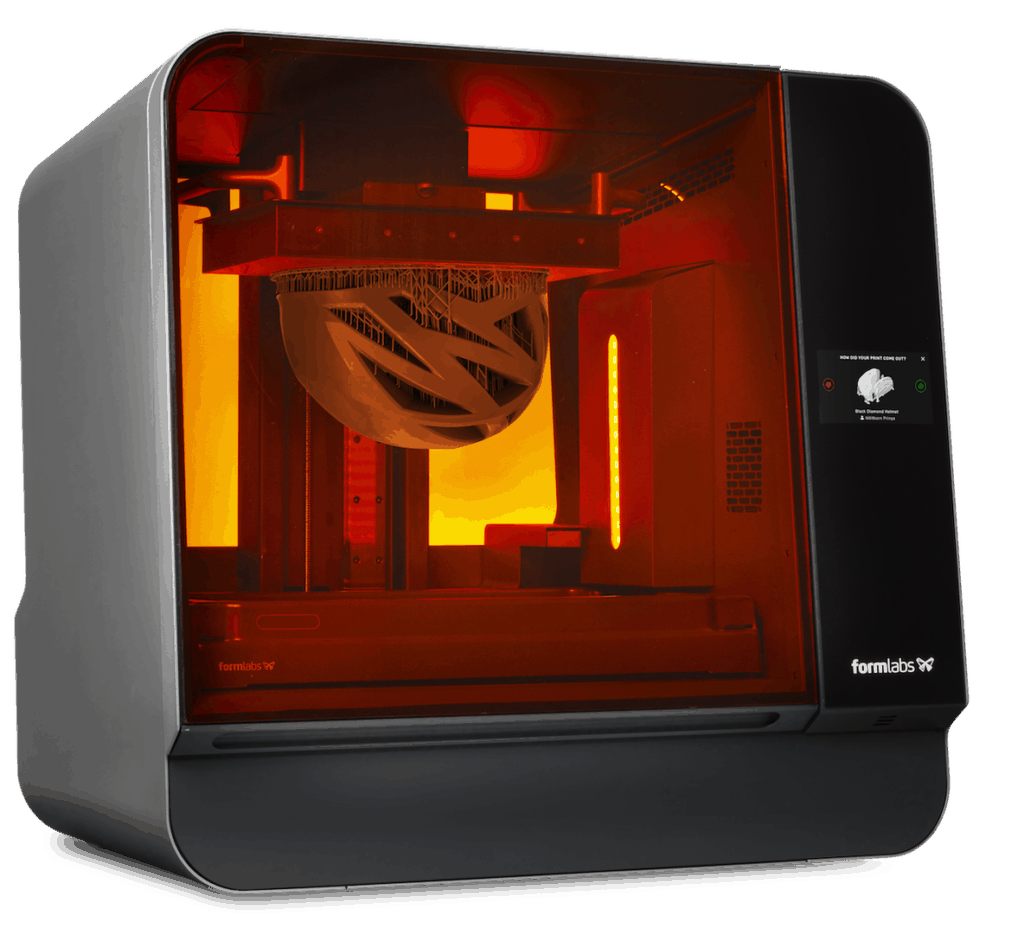

InSource DMT runs state-of-the-art 3D printers from Formlabs and Ultimaker 5S. With a large selection of materials featuring different characteristics we can 3D print your parts exactly to your specifications.

- Stereolithography (SLA) 3D Printing

- Selective Laser Sintering (SLS)

- Fuse Deposition Modeling (FDM)

- High-Strength Reinforced 3D Printing

We provide Engraving, etching, and surface marks on most metals and color changes on various plastics using a class 1 certified GeoMark PRO laser marking system.

- Annealing

- Dark Marking / Heat Marks

- Etching / Ablation

- Engraving / Cutting

- Discoloration / Foaming

- Carbon Migration

- Carbonization

Quality Control & Certifications

We are committed to a quality system that strive to meet and exceed our customer and create a higher level of customer and co-worker satisfaction. We exercise this commitment by:

- Complying with established standard and customers requirement.

- Maintaining and continually improving the effectiveness of our processes and services

- Reviewing quality objectives regularly to ensure that our quality systems remain appropriate and effective.

CERTIFICATIONS

- ISO 9001:2015 Quality Standard ISO #235989

- ITAR Register and compliant ITAR #M34460

- IPC/WHMA-A-620, #A620DS-25091844116

- JCP Registered

- Gidep Registered

- BBB Accredited

DUNS #: 056147179

CAGE CODE: 72BQ3

NAIC CODES:

541330, 334220, 334419, 332710, 336413, 541340, 811219